We continue our series of blogposts covering the development of fabrics for use in upholstery, the use of different fibres, and the development of different weaves and designs. Blogpost 4 in the series begins the differing types of weaves that are used in upholstery fabrics, with us covering the herringbone, satin and sateen weaves below:

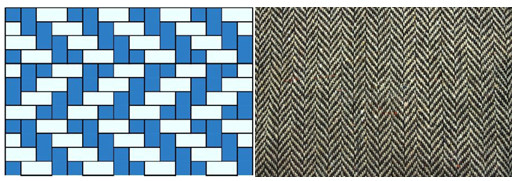

Herringbone:

Herringbone:

This refers to a broken twill weave (see above) which gives a zig zag pattern. It is distinguished from a plain chevron by the break at reversal, which makes it resemble a broken zigzag.

Other than the attractiveness of its arrowhead design, it has all the other qualities of a twill weave. Fabric produced using a herringbone weave is normally made of wool.

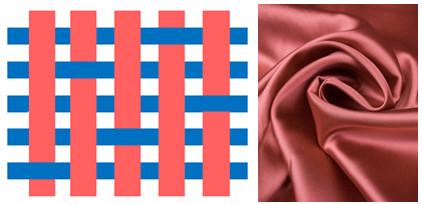

Satin:

A Satin weave is constructed by floating several warp yarns across the weft before going under 1 weft thread, and beginning the cycle again. Having fewer crossovers leads to the smooth surface of the finished fabric. Satin is normally produced using silk fibre, although nylon and polyester can also be used.

Although a variation of the the twill weave, Satin weave structures move the weft intersection across at least 1 warp thread before beginning the cycle again. A disadvantage of a satin weave is that the fabric fibres will snag easily.

If you’re using cotton fibres, the fabric you produce is Sateen (see below). Satin weaves are predominantly warp float facing, whereas Sateen is weft float facing.

Sateen:

Sateen:

A sateen weave is essentially a satin weave (see above) but using short staple yarns like cotton. The floats will be in the weft direction ie continuous weft yarn, with as few interruptions of warp as possible. The fabric produced is not as lustrous as the satin weave fabric but they are more durable. Sateen weaves are predominantly weft float facing, whereas Satin is warp float facing.